Technical

1.Suitable for roller conveyor?

State of the goods:

For roller conveyor contact bottom should level off, hard goods, such as: hard carton, flat plastic box, metal (steel) material box, wooden pallets, etc. And when the goods contact underside is soft or irregular (such as: soft bags, handbags, irregular bottom parts, etc.), is unfit for roller conveyor.

Goods and roller interface is too small (point contact and line contact), easily damaged roller (partial wear, taper sleeve damaged, etc.).

Environment state:

1. Plastic in low temperature brittleness is big, not suitable for long time using. Different roller has its applicable temperature (see the characteristics of various series of products), when in excess of the prescribed temperature range, please contact us and confirmed;

2.Package glue roller after use will produce a small amount of "powder", so cannot be used in dust-free environment;

3.Pu yi adsorption outside color, therefore cannot be used for conveying with color printing packing and goods.

2.Roll how many appropriate?

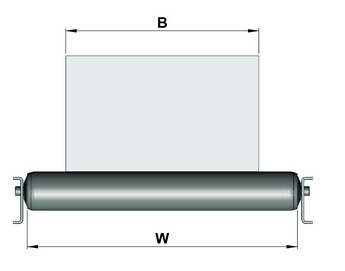

Different width of goods should select suitable roller length (the length of the roll surface, expressed in W), for the straight line segment, the conveying can generally to refer to the following formula:

W=W+△B

Type:B — width of goods ;△B — width margin,generally take 50~150(mm)

For rigid at the bottom of the big goods, in does not affect the normal delivery and security, under the condition of the goods length and width can be slightly bigger than the roll surface generally seek:W≥0.8B。

3、The setting of the roller spacing:

In order to ensure the smooth delivery of the goods, roller spacing (namely the center distance, expressed in T) selection principle is: delivery at any time, at least more than 3 roller support goods,be T≤1/3L。

1.For smooth delivery of the goods, preferable T = (1/4 ~ 1/5) L or smaller;

2.For slender flexible large goods, still need to consider the goods around degrees: the goods around on a roller spacing should be less than 1/500 of the roller spacing, otherwise it will greatly increase the running resistance;

3.Setting of the spacing of double chain conveyor must also satisfy formula:T=n*p/2;

4.Wedge belt wheel roller spacing selection, are restrained by their wedge with more models, see P49 related instructions. At the same time also need to confirm each roller bearing cannot exceed the maximum static load, the load is no impact under uniformly distributed load, such as concentrated load, also need to increase safety factor).

4、Different kinds of transportation:

1.When using artificial, or tilted free fall without power delivery:

◇Plastic housings: 1200 series

◇Steel bearing: 1100, 1800, etc

2.If use ac gear motor drive, or driven by electric roller and so on power delivery:

◇"O" drive belt: 2240, 2260, etc

◇Wedge belt: 2250 series

◇Chain transmission: 2214/2224 series (model steel sprocket, plastic housings); 2411/2421 series (steel sprocket, plastic housings); 2311/2321 series (steel sprocket, steel bearing)

3.When using ac gear motor drive, and I need to stop goods on the online store such as friction product conveyor:

◇ Sleeve product put: 3214/3224 series (model steel sprocket); 3211/3221 series (steel sprocket)

◇Adjustable product put: 3816/3826 series (steel sprocket)

4.When the goods need to transport the turn:

◇Plastic cone set of classes: 1600, 2640, 2660, 2650, 2660 series

◇Steel cone roller type: 1500, 2521 series